Our Whiteheart Malleable Cast Iron Pipe Fittings brand EE are used in threaded pipe connections, particularly:

- in water supply systems

- gas and steam systems

- central heating systems

- sprinkler systems

- to convey non-aggressive

- liquids and gases.

MALLEABLE IRON FITTINGS – TECHNICAL CHARACTERISTICS

MANUFACTURING NORMATIVE

Our EE brand malleable iron fittings are manufactured according to international normative EN 10242 and ISO49, the construction symbol “A”

MATERIAL

Fittings: white malleable EN-GJMW-400-5 cast iron, according to EN 1562, equivalent to W 40-05 ,according to ISO 5922.

SURFACE/ZINC PLATING

EE brand fittings can be supplied in accordance to order: with black or galvanized surface According to EN 10242, zinc oating weight relative to the surface exceeds 500 gr/m², which corresponds to an average layer thickness of 70micron. Both black and galvanized surfaces are protected against corrosion. Corrosion protection substance does not contain polycyclic aromatic hydrocarbons.

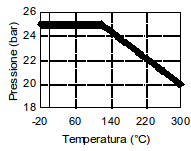

OPERATING PRESSURE

Our Malleable Iron Fittings can perform at the highest admissible working pressure and temperature ranges quoted in the left table.

Constructional symbol A is characterized by the following material: whiteheart, malleable cast iron EN-GJMW-400-5.

- 2.5 MPa/25 bar/ at the temp. from -20°C to 120°C

- 2.0 MPa/20 bar/ at the temp. of 300°C

LEAK TEST

According to EN 10242, each EE brand fitting is subjected to a leak test at air pressure of at least 0,5 MPa / 5 bar, which is equivalent to a minimum hydrostatic pressure of 2.0 MPa / 20 bar/.

THE THREADS

Fittings have the threads in accordance with ISO 7-1:

- external – conical (R)

- internal – cylindrical (Rp)

CONIAL UNIONS

Conical unions (tightened on a taper) should be assembled using minimal tightening moment:

| Dimension in inches | 3/8 | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 |

| Tightening moment Nm | 60 | 90 | 120 | 170 | 210 | 250 | 340 | 420 | 500 | 600 |

NOTE: Conical unions and conical union details cannot be used twice because it will not guarantee the joint leak tightness.

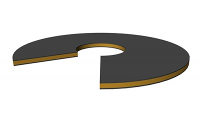

THE GASKETS

The material for gaskets depends on the usage (the transmitted factor, temperature). The gaskets of our unions are made of synthetic fibers which do not contain asbestos:

- Max working temperature standard 155 C°

- Max working temperature standard 130 C°

The thickness of gaskets for flat unions from 3/8 ÷ 11/2”- 2 mm and from 2 ÷ 4” – 3 mm. The gaskets and other seals measures to the threads used by the customers shall comply with the requirements and standards appropriate to the type of installation.

Flat unions require the following dimensions of gaskets:

Flat unions require the following dimensions of gaskets:

| Dimensions of Unions in Inches | Inner diameter (Union size mm) | Outer diameter (Union size mm) | Thread dimension of Union Nuts |

| 3/8 | 19 | 27 | G7/8 |

| 1/2 | 24 | 34 | G11/8 |

| 3/4 | 27 | 38 | G11/4 |

| 1 | 32 | 44 | G11/2 |

| 11/4 | 42 | 55 | G2 |

| 11/2 | 46 | 62 | G21/4 |

| 2 | 60 | 78 | G23/4 |

| 21/2 | 75 | 97 | G31/2 |

| 3 | 88 | 110 | G4 |

| 4 | 120 | 148 | G5 1/2 |